Products

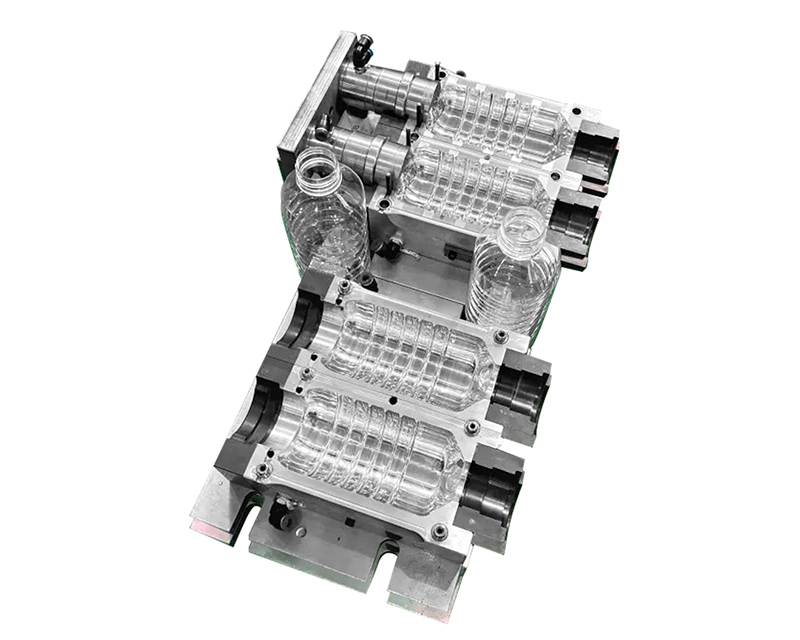

Blowing Mould

Product Features

① The template is made of stainless steel or P20 pre-hardened, and the P20 template is nickel-plated, with a Rockwell hardness of 38~40 degrees.

② The core, cavity and screw mouth are made of Swedish ASSAB S136 or German 2316, with a Rockwell hardness of 48~52 degrees.

③ Graphite copper plates are inlaid between the slider and the push plate, and between the guide column and the guide sleeve to achieve better lubrication.

④ The heating ring of each cavity is made of Italian ROTFEL or German HOTSET.

⑤ The ejector pin is made of Japanese SKD-61, with a Rockwell hardness of 48~50 degrees.

⑥ The heat insulation cap is made of American DUPONT P84NT2 polyimide, with a long-term use temperature of 380℃ and a short-term high temperature of 600℃.

⑦ The injection copper nozzle is made of Italian beryllium bronze with a Rockwell hardness of 38 degrees.

Detailed description

We are a technology company focusing on the R&D and manufacturing of PET preform molds. We have 20 years of industry experience and are committed to providing high-quality, high-precision PET preform mold solutions to global customers. The factory covers an area of 1,000 square meters, equipped with advanced processing equipment and technical teams, and our products are exported to more than 30 countries and regions including Europe, America, Southeast Asia, etc.。

Detailed explanation of professional PET preform mold manufacturing capabilities

一、Precision design and R&D capabilities

-

Digital design platform:

-

Use UG NX, Pro/E and other 3D design software

-

Equipped with Moldflow mold flow analysis system

-

Can complete complex preform structure simulation analysis

-

Design accuracy reaches 0.001mm level

-

Professional R&D team:

(Number of cavities) |

caliber) |

application |

18 cav |

48mm, 38mm,30/25,20/25, PCO1881, PCO1810 |

Water, juice, carbonated drinks, daily chemicals, cooking oil, medicines |

24 cav |

48mm,38mm,30/25,29/25, PCO1881, PCO1810 |

Water, juice, carbonated drinks, daily chemicals, cooking oil, medicines |

32 cav |

48mm,38mm,30/25,29/25, PCO1881, PCO1810 |

Water, juice, carbonated drinks, daily chemicals, cooking oil, medicines |

48 cav |

48mm,38mm,30/25,29/25, PCO1881, PCO1810 |

Water, juice, carbonated drinks, daily chemicals, cooking oil, medicines |

56 cav |

48mm, 38mm, 30/25, 29/25, PCO1881, PCO1810 |

Water, juice, carbonated drinks, daily chemicals, cooking oil, medicines |

72 cav |

38mm, 30/25,29/25, PCO1881, PCO1810 |

Water, juice, carbonated drinks, daily chemicals, cooking oil, medicines |

96 cav |

38mm, 30/25, 29/25, PCO1881, PCO1810 |

Water, juice, carbonated drinks, daily chemicals, cooking oil, medicines/span> |

112 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, juice, carbonated drinks, daily chemicals, cooking oil, medicines |

128 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, juice, carbonated drinks, daily chemicals, cooking oil, medicines |

144 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, juice, carbonated drinks, daily chemicals, cooking oil, medicines |

176 cav |

30/25, 29/25, PCO1881, PCO1810 |

Water, juice, carbonated drinks, daily chemicals, cooking oil, medicines |

We continue to invest 8% of our annual turnover in technology upgrades and equipment updates to ensure that our manufacturing capabilities always remain at the leading level in the industry. With a complete manufacturing system and strict quality control, we have provided more than 5,000 sets of high-quality PET preform molds to more than 300 customers around the world.